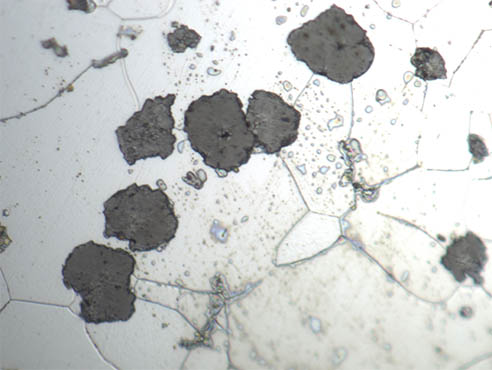

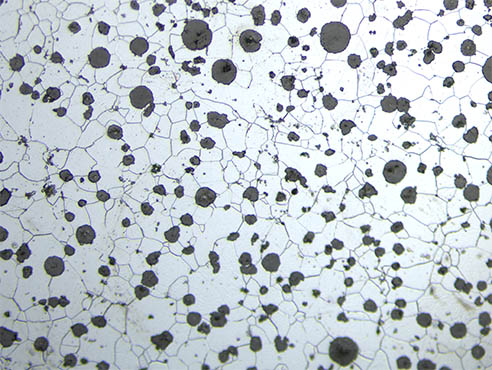

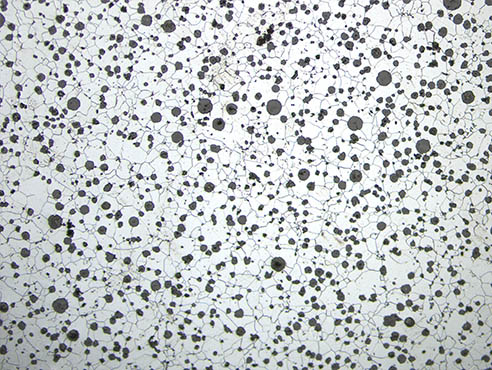

Due to its good toughness and high wear resistance, ductile iron is often used in various products with high quality control requirements, such as automobile crankshafts, water supply or sewer pipes. High quality control for cast iron. So, how do we analyze ductile iron? The microstructure of cast iron can be characterized by metallographic microscope and image analysis software.

MSHOT metallographic microscope MJ43 can observe the size, shape, spheroidization rate and distribution information of graphite, providing important reference data for relevant industry personnel.

The epi/transmission light sources of the metallographic microscope are all self-developed light sources. The epi-illumination light source is a wide-spectrum MG-30 (halogen light source is optional), and the transmitted light source is a warm color temperature LED light source, equipped with a light intensity manager; according to industrial and material science Different applications, through modular combination, can realize a variety of observation methods: brightfield, darkfield, polarized light, fluorescence, DIC, etc.

MJ43 is mainly used in semiconductor, FPD, circuit boards, metal materials, tools and other manufacturing fields, suitable for teaching and research.

If you would like to get more information, you could visit www.m-shot.com.