With the advent of high-power LED lights, there are many new choices for the light sources of higher education instruments and scientific research instruments. Especially in the field of fluorescent observation application, LED lamp has the characteristics of good monochromatic, no ultraviolet, infrared radiation, stable color temperature, long service life, no waiting time, and continuous brightness adjustment, gradually replacing the traditional mercury lamp, xenon lamp, halogen lamp and other light sources. But the LED lamp also has some disadvantages. Its disadvantage is that the working temperature has a great influence on the photoelectric and electrical parameters of the LED. However, the heat generated by the LED lamp can not be exported through ultraviolet or infrared as the traditional lamp. Therefore, in addition to illuminance, the performance of heat dissipation system should be considered when evaluating an excellent LED fluorescent light source.

First of all, let's understand the influence of LED operating temperature on LED performance?

Note: the working temperature here refers to the PN junction temperature of LED, referred to as junction temperature.

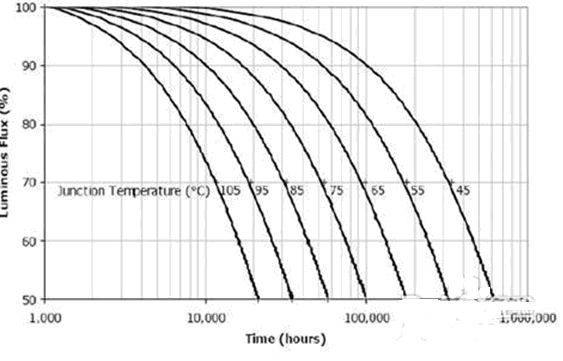

Image 1

1. Impact on service life

Unlike other light sources, LED does not go out suddenly, but the luminous efficiency gradually declines. At present, the life of LED is evaluated by judging the light attenuation of LED, and the time of light flux attenuation of 30% is usually defined as the life of LED. The following is the influence of LED PN junction temperature on LED life.

It can be seen from the figure that the light decay of LED is related to its junction temperature. The higher the junction temperature, the earlier the light decay occurs, that is, the shorter the lifetime. As can be seen from the figure, if the junction temperature is 105 degrees, the lifetime of brightness falling to 70% is only more than 10000 hours, and that of 95 degrees is 20000 hours. If the junction temperature is reduced to 75 degrees, the lifetime is 50000 hours, and that of 65 degrees can be extended to 90000 hours. So the key to prolong the lifetime is to reduce the junction temperature. However, these data are only suitable for Cree's LEDs, not for the LEDs of other companies.

2. The influence on the luminescence wavelength

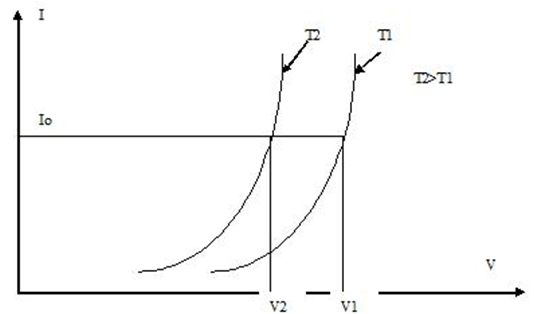

The high working temperature of LED will affect the shift of the main wavelength of led to long wavelength. The relationship between the main wavelength of LED and temperature can be expressed as λ P (t ') = λ 0 (T0) + △ TJ × 0.1nm / ℃. It can be seen from the formula that when the PN junction temperature increases by 10 ℃, the wavelength shifts to the long wavelength by 1 nm, and the uniformity and consistency of luminescence become worse. The wavelength change has a great influence on the excitation efficiency of the fluorescent probe. It not only affects the experimental and diagnostic results, but also increases the cost. The fluorescent probe is very expensive! Now we clearly understand how important it is to reduce the junction temperature of LED fluorescent light source, whether it is the stability of optical parameters or service life. So how to detect the junction temperature of LED lamp? You know, the PN junction of LED is inside the LED. You can't put a thermometer or thermocouple into the PN junction to measure its temperature. Fortunately, we have an indirect method to measure the temperature, which is to measure the forward voltage of the LED when it is working. This is the use of LED volt ampere characteristics of the temperature characteristics. As shown in Figure 2

Assuming that the LED is supplied with Constant Current IO, when the junction temperature is T1, the voltage is V1, and when the junction temperature rises to T2, the whole volt ampere characteristic shifts to the left, the Current IO remains unchanged, and the voltage changes to v2. The temperature coefficient, expressed in MV / OC, can be obtained when the two voltage differences are removed by temperature. For ordinary silicon diodes, the temperature coefficient is about - 2mV / OC. But most of the LEDs are not made of silicon, so its temperature coefficient needs to be determined separately. Fortunately, most of the data sheets of LED manufacturers give its temperature coefficient. For example, the temperature coefficient of xlamp7090xr-e high-power LED is - 4MV / OC. It's twice as big as a normal silicon diode.

Image 2

Assuming that the LED is supplied with Constant Current IO, when the junction temperature is T1, the voltage is V1, and when the junction temperature rises to T2, the whole volt ampere characteristic shifts to the left, the Current IO remains unchanged, and the voltage changes to v2. The temperature coefficient, expressed in MV / OC, can be obtained when the two voltage differences are removed by temperature. For ordinary silicon diodes, the temperature coefficient is about - 2mV / OC. But most of the LEDs are not made of silicon, so its temperature coefficient needs to be determined separately. Fortunately, most of the data sheets of LED manufacturers give its temperature coefficient. For example, the temperature coefficient of xlamp7090xr-e high-power LED is - 4MV / OC. It's twice as big as a normal silicon diode.

Now that we know the method, let's experiment together! We take a high-power blue LED lamp of Cree company as an example (ha ha! The LED fluorescent module of our company is the LED lamp. To explain how to measure the junction temperature of LED, so as to judge the advantages and disadvantages of LED fluorescent light source. First of all, we need to prepare equipment: a multimeter, a number of wires, a constant current driven LED light source. Here I prepared the blue single excitation led fluorescence module mf-b-led LED LED fluorescence light source developed by our company.

Two wires are led out from both ends of the LED. The positive electrode is connected with the red contact pen of the multimeter, and the negative electrode is connected with the black contact pen of the multimeter. The gear is adjusted to the DC voltage range of 20V. Connect the power, gently press the switch, while the LED is not hot up, immediately read the voltmeter reading, that is, V1 value. Then read the readings every 1 hour. Until the reading voltage remains unchanged (the same for several consecutive readings), the whole light source has reached the thermal balance. Table 1 shows the measured data.

Time |

Forward voltage(V) |

Ambient temperature℃ |

21:00(Start) |

2.90 |

27 |

22:00 |

2.80 |

27 |

23:00 |

2.81 |

27 |

Next 09:00AM |

2.81 |

27 |

10:00 |

2.81 |

27 |

11:00 |

2.81 |

28 |

It can be seen from the above table that:

V1=2.90V ,V2=2.81V。

V = v2-v1 = - 0.09v, we know that the temperature coefficient of this led lamp bead is - 3.3mV / ℃

So the temperature rise of PN? TJ = - 0.09 * 1000 / - 3.3 = 27.3 ℃.

Then the ambient temperature is 27 ℃. So the temperature of PN junction TJ = 27.3 + 27 = 54.3 ℃.

According to figure 1, the service life of this LED fluorescent light source can reach more than 100000 hours.

Main wavelength offset △ λ P (t ′) = △ TJ × 0.1nm / ℃ = 27.3 * 0.1 = 2.7nm

Has everyone learned? How to predict the life of LED fluorescent light source, how to determine the optical parameters of LED fluorescent light source.